Welcome customer, what can we help you with today?

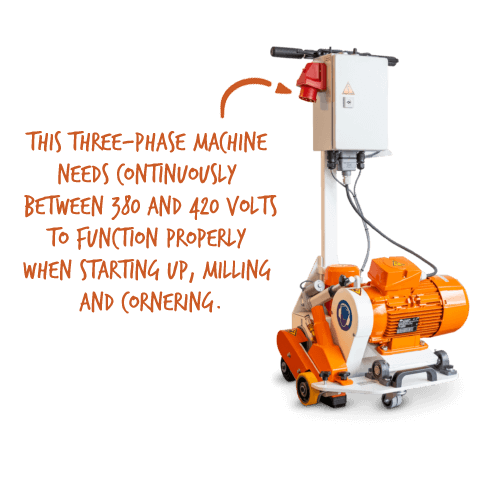

Congratulations customer! You are the user of a D4.0: a completely self-propelled underfloor heating milling machine with serial number (unknown).

This machine is extremely comfortable and built for your convenience. If something does not go quite as it should, you will find useful instructions on this service page so that you can quickly continue milling.

Here, we also give you a number of handy tips for the maintenance and use of your underfloor heating milling machine and you will find an overview of products that you can order to make your machine function optimally.

The instructions in our service videos are step-by-step and clearly formulated. Do you still have a question or would you rather speak to one of our enthusiastic colleagues? Then click on the links below.

The right tools for your D4.0

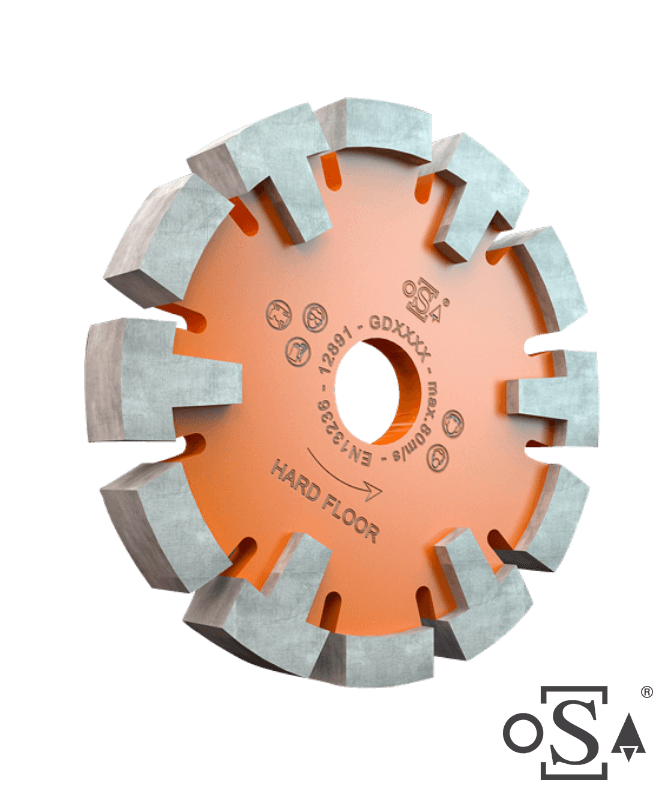

Diamond is your best friend.

Warning!

Do you perform maintenance on your machine? Or do you perform activities other than milling? Always make sure that the power plug is removed from the socket so that there is no longer any voltage on the machine and that the plug remains in your field of view.

Products for your machine

Useful products for using your milling machine.

Take care!

Your machine will continue to work perfectly if you maintain it properly. We are happy to help you with these tips to keep your machine in the best form.

- Do you perform maintenance on your machine? or operations other than milling? Make sure that the plug is removed at all times and that it remains in your field of view.

- Make sure you use the correct disc for the correct surface. If used incorrectly, the disc wears much faster and can potentially damage your machine.

- Keep in mind that the amp meter shows a maximum of 9 amps. Does the amp meter read more than 9 amps? Then check the disk you are using More than 9 or even 10 amps can overload and damage the machine.

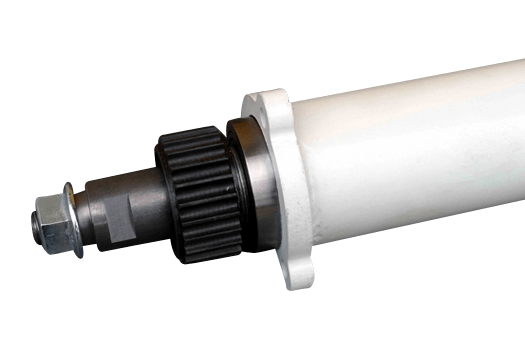

- After every 10 to 12 milling jobs, remove the saw hood and coupling cover and remove dust and dirt. This prevents accumulation D39problems with the clutch and the saw shaft or the pointed belt.

Exploded view

Are you looking for a specific part?

In this schematic view you can see exactly where which part is located.

Click on an image to enlarge.

Ask Leendert-Jan or Remco

Do you still have any questions? Or are you having trouble with our instructional videos? Our account managers can tell you everything about the floorIQ tools. They can also make a repair appointment if necessary.