This is how it works

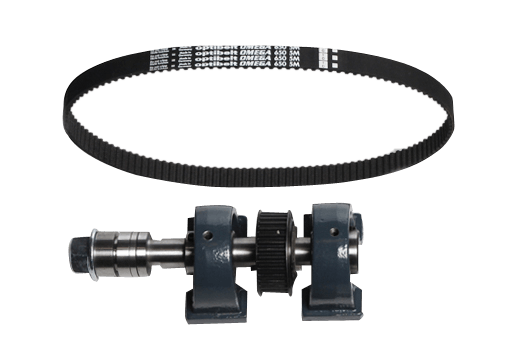

Step 1: FloorIQ’s floor heating milling machine allows you to cut even slots in one operation quickly and easily. The machine cuts slots effortlessly in an existing screed, cement floor, concrete floor (400V) or tiled floor (400V).

Step 2: As the machine cuts neat and regular slots, the heating pipes can be laid directly in the slots.

Step 3: After the pipes have been tested, the slots can be sealed with tile adhesive.

Step 4: The top floor – tiles, parquet, marble or granite – can be laid directly onto the sealed slots. All this can be done in just two days.

The advantages of our machines

In combination with our wide range of tuck point blades, our machines are suitable for many different types of floors, including existing tiled floors.

Ask Leendert-Jan

Our account manager can tell you everything you need to know about FloorIQ diamond tools.